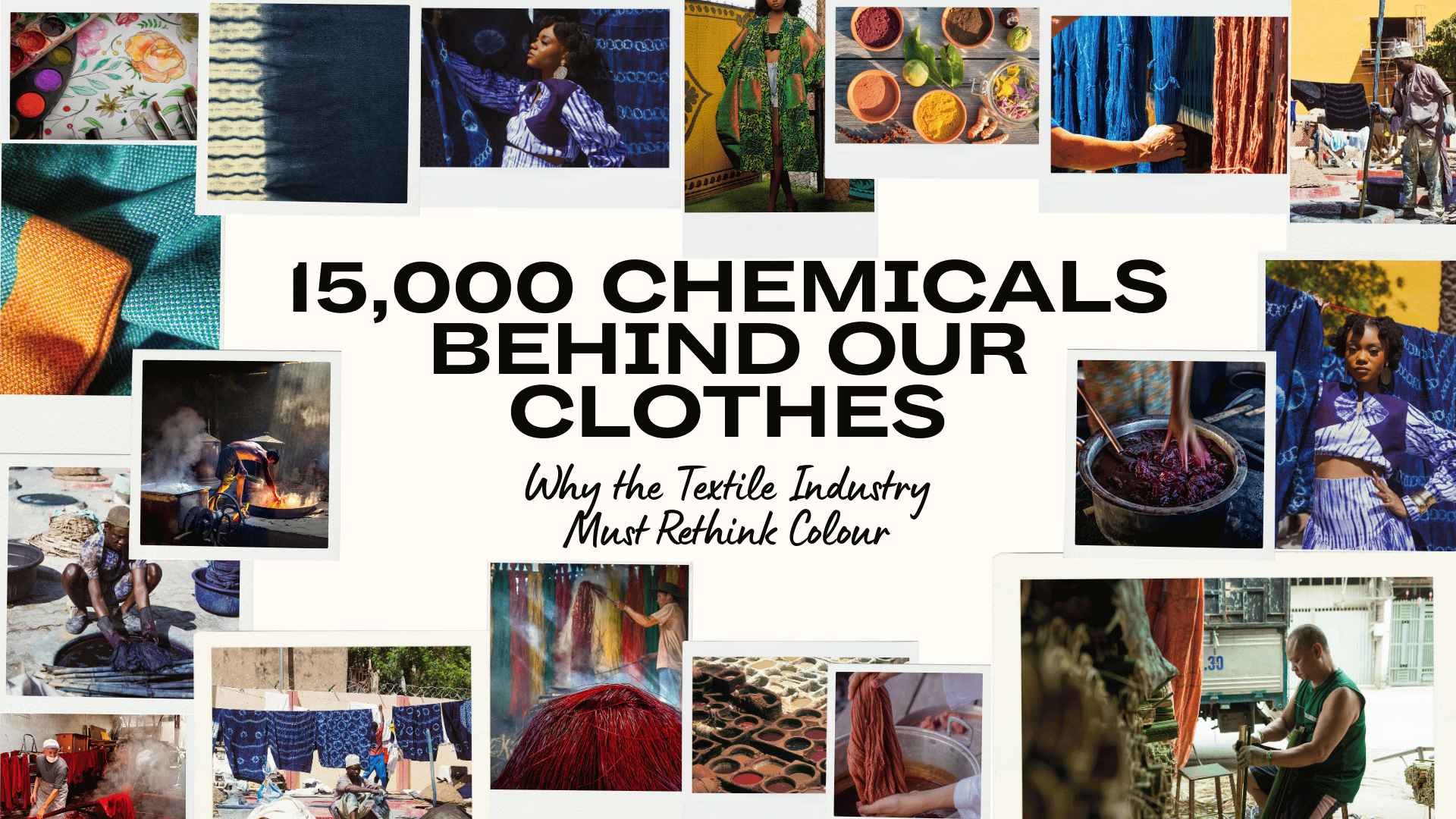

Over 15,000 chemicals are used in textile dyeing worldwide, impacting water health and ecosystems. Learn how DyeMaster is enabling safer sustainable colour solutions.

By Govind Singh Rathore

Every coloured textile tells a powerful story. A vibrant kurta a soft cotton bedsheet or a dyed scarf all rely on colour to appeal to consumers. Yet behind this visual beauty lies a chemical footprint that often remains invisible.

Textile dyeing and finishing processes use more than 15,000 chemical substances globally, many of which eventually enter rivers soil air and even human skin. For decades colour has been prioritised for speed brightness and cost efficiency. Today environmental realities demand a more responsible approach.

With rising regulatory pressure informed consumers and global sustainability goals the industry must rethink how colour is created. This transition is where DyeMaster is helping redefine the future of textile dyeing.

Table of Contents

- Introduction

- The Environmental Cost of Conventional Dyeing

- How Textile Chemicals Impact Human Health

- Why Effluent Treatment Alone Is Not Enough

- How DyeMaster Is Redesigning Colour

- A Practical Roadmap to Cleaner Colour

- Colour With Conscience The Way Forward

The Environmental Cost of Conventional Dyeing

Textile dyeing is one of the most resource intensive stages in fabric production. Nearly 20 percent of global industrial water pollution is linked to textile processing and dyeing.

Conventional dye houses rely heavily on synthetic dyes Azo based colourants heavy metals and chemical auxiliaries. The consequences are widespread.

- Millions of litres of wastewater are released daily carrying residual dyes salts and chemicals

- Rivers lose oxygen and sunlight causing long term damage to aquatic ecosystems

- Toxic residues accumulate in soil affecting agriculture and groundwater

- Pollution continues long after garments reach consumers

The risks associated with one of the most widely used dye groups are explained in detail in From Runway to Risk The Harmful Effects of Azo Dyes in Textiles, which highlights why eliminating Azo dyes is critical for industry transformation.

on Remediation of Dyes,

Dye Intermediates and

Textile Industrial Waste

What These Chemicals Mean for Human Health

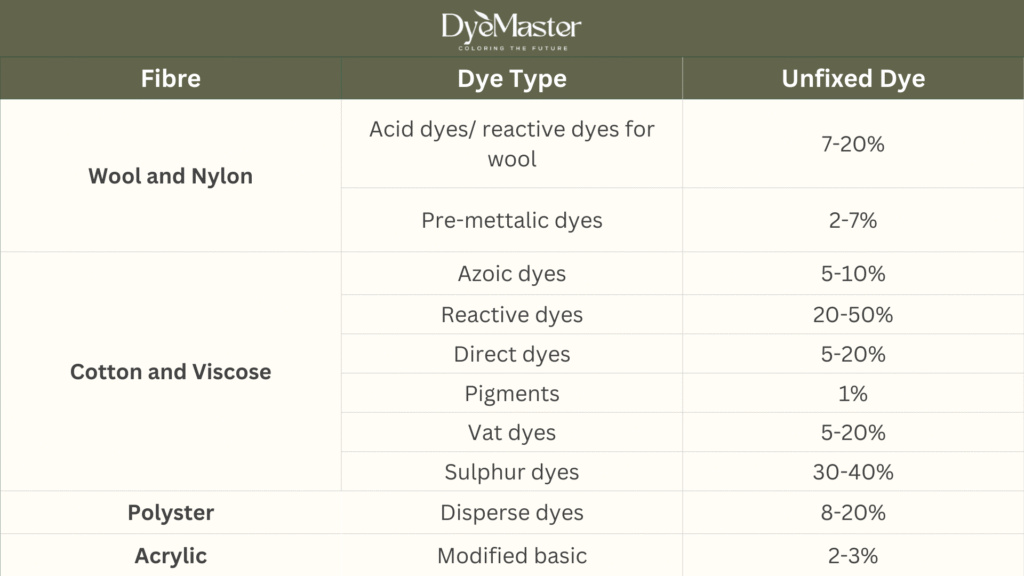

The effects of chemical dyeing extend far beyond the factory floor. Studies indicate that up to 10 percent of dyes used in textiles fail to bind with fabric, remaining as residues.

For consumers this often results in

- Skin irritation redness and itching

- Allergic reactions especially among children

- Reduced breathability caused by chemical finishes

- Growing concerns around long term exposure

As awareness grows brands and buyers actively look for safer solutions. DyeMaster supports this shift through knowledge driven content such as 7 Expert Tips for Achieving Bold Long Lasting Colours with Natural Dyes, which explains how colour performance and safety can coexist.

Why Effluent Treatment Alone Is Not Enough

Effluent treatment plants play a necessary role but they address pollution only after it has already occurred. Treating wastewater does not remove the core problem.

True sustainability begins at the source.

A responsible dyeing approach focuses on

- Using inherently safer dye inputs

- Reducing chemical load within dye baths

- Cutting water usage which can exceed 100 litres per kilogram of fabric in conventional systems

- Lowering salt and energy consumption

- Making effluent easier and less costly to treat

This source first approach is explored further in The Power of Plants How Non Toxic Biodegradable Dyes Are Changing Fashion, which explains how plant based solutions are redefining modern dyeing.

How DyeMaster Is Redesigning Colour

DyeMaster believes colour should never compromise health environmental safety or performance. The brand works closely with mills to make sustainable dyeing both practical and scalable.

1. Safer Chemistry

DyeMaster prioritises Azo free non toxic and biodegradable dyes that significantly reduce environmental and occupational risks.

2. Performance Without Compromise

Optimised dye recipes help manufacturers achieve deep consistent shades with strong fastness properties. The creative possibilities of natural colour are showcased in Beyond Beige 5 Bold Natural Dye Colours You Did Not Know Existed.

3. Practical Industry Support

From pre treatment to mordanting and washing DyeMaster provides real world guidance tailored for working dye houses. Ongoing insights and applications can be explored through the DyeMaster Blog, which serves as a growing knowledge hub for sustainable dyeing.

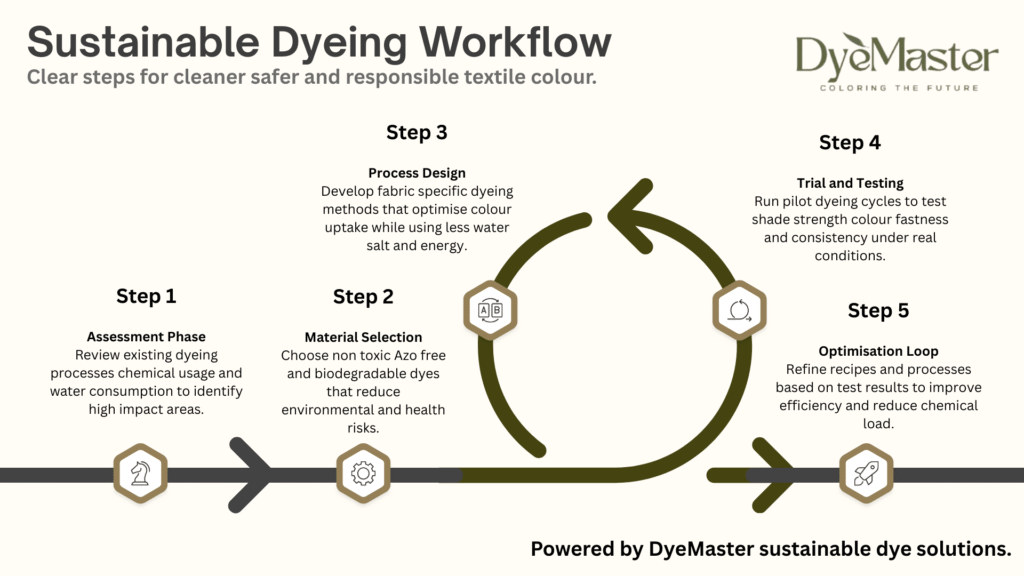

A Practical Roadmap to Cleaner Colour

Transitioning to sustainable dyeing does not require shutting down operations. Even a 20 to 30 percent reduction in chemical usage can significantly reduce effluent load.

Manufacturers can begin with five practical steps.

- Audit all chemicals used in dyeing and finishing

- Replace high risk dyes starting with babywear home textiles and export orders

- Introduce low impact dye recipes operating at lower temperatures

- Train production teams on new processes

- Share improvements transparently with buyers

For inspiration manufacturers can explore heritage and innovation coming together through the beauty of batik and modern fashion applications of batik dyeing techniques, both of which demonstrate how traditional methods align with contemporary sustainability goals.

Colour With Conscience The Way Forward

The number 15,000 is not just a statistic. It reflects the scale of responsibility the textile industry carries today. Colour must now be part of conversations on water conservation worker safety climate resilience and consumer trust.

A responsible future includes

- Rivers that run clear

- Safer working conditions inside dye houses

- Garments that touch the skin without hidden harm

DyeMaster invites mills brands and designers to begin their clean colour journey by exploring sustainable dye solutions collaborating on pilot projects and building transparent colour stories.

Those ready to take the next step can connect directly through the DyeMaster contact page to discuss how cleaner colour can be integrated into their production processes.

When colour is created with conscience the textile industry does not just look better it becomes better for people the planet and the future of fashion.

FAQ

1. Why does the textile industry use so many chemicals in dyeing

Textile dyeing involves multiple stages such as fabric preparation dye application colour fixing and finishing. Each stage uses specific chemical agents to achieve colour strength durability and consistency. This is why more than 15,000 chemicals are used across the global textile value chain. DyeMaster focuses on reducing this dependency by promoting safer alternatives explained in its article on how non toxic biodegradable dyes are changing fashion.

2. What are Azo dyes and why are they harmful

Azo dyes are synthetic dyes commonly used to achieve bright colours at low cost. Some Azo dyes can break down into harmful aromatic amines that pose risks to human health and the environment. Many countries now restrict their use. The environmental and health impact of these dyes is explained in detail in DyeMaster’s article on the harmful effects of Azo dyes in textiles.

3. Can natural dyes give strong and long lasting colours

Yes natural dyes can produce rich and long lasting colours when applied using correct dyeing techniques. Factors such as proper fabric preparation mordant selection and process control play an important role. DyeMaster shares practical guidance on this in its blog on expert tips for achieving bold long lasting colours with natural dyes.

4. How do sustainable dyes help reduce water pollution

Sustainable dyes bind more effectively to fabric which reduces dye loss during washing and rinsing. They also require fewer chemicals and lower salt levels making wastewater easier to treat. This approach of reducing pollution at the source is explained further in DyeMaster’s article on how non toxic biodegradable dyes are changing fashion.

5. Are sustainable dyes suitable for large scale textile production

Yes sustainable dyes are increasingly being adopted by textile mills at commercial scale. With the right technical support manufacturers can achieve consistent colour quality while reducing environmental impact. Real world applications and industry insights are regularly shared on the DyeMaster blog.

6. Do natural dyes limit colour options for designers

No natural dyes offer a wide and versatile colour palette ranging from soft pastels to deep bold shades. Modern techniques allow designers to explore creative possibilities without compromising sustainability. DyeMaster highlights this potential in its article on five bold natural dye colours you did not know existed.

7. How can textile manufacturers start using cleaner dyeing practices

Manufacturers can start by reviewing existing chemicals replacing high risk dyes and introducing low impact dye recipes gradually. Running small pilot trials and training teams helps ensure a smooth transition. Inspiration can also be drawn from traditional and modern dyeing methods discussed in the beauty of batik and exploring modern fashion with batik dyeing techniques. For customised guidance manufacturers can directly connect through the DyeMaster contact page